First published by Sustainability Matters.

“If you’re not processing your wastewater and getting all the energy you can out of it, it’s a waste and you’re losing out,” says Wiley Process Engineer Heath Barker. In this article, Barker talks about the latest trends in covered anaerobic lagoon (CAL) systems and how they need to be nurtured to achieve maximum benefits.

Following recent government policy shifts such as the Carbon Pricing Scheme and the Clean Technology Investment Program, many industrial sites that use biological wastewater treatment lagoons have installed covered anaerobic lagoon (CAL) systems. These CAL systems are targeting more efficient effluent treatment methods that both reduce emissions and capture biogas as an on-site renewable energy source.

Barker points out that some systems can be quite basic with a simple cover applied to an existing pond to capture the biogas which is then flared off. “While this will reduce carbon emissions, companies [with these basic systems] are missing out on opportunities to harness that energy.”

How can the CAL system harness energy?

“Any company with an organic waste stream, such as abattoirs, dairies, breweries, pig farms and chicken farms, may benefit from the implementation of a CAL system for biogas recovery from wastewater,” said Barker.

Existing anaerobic lagoons can be easily covered with high-density polyethylene (HDPE) to capture the biogas released from the lagoon. This gas can be burned through the boiler to provide energy for the processing plant.

“It can be tricky dealing with all the rules and regulations for handling the biogas, and it can vary from state to state,” said Barker. “But, if you have the right people it can be easy.”

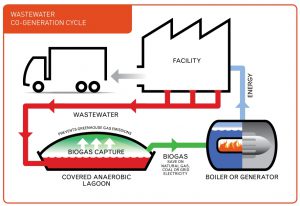

Figure 1 shows how a typical covered anaerobic lagoon system works at a meat processing plant.

Figure 1.

How can the system be optimised?

Barker points out that it’s important to remember that anaerobic systems are ‘living’ biological systems, and to get the most out of them, you need to nurture them just like you would nurture your pet.

“By improving your biogas yield, your anaerobic treatment will also be improved. This occurs because more organics are being converted to biogas and means there will be fewer organics in the waste stream.

“These days it is not uncommon to achieve 90% chemical oxygen demand (COD) reduction with these anaerobic digestion systems.”

Wastewater quality monitoring and pre-treatment equipment combined with CAL technology can be used to optimise the generation of biogas.

Barker explained that, just as you wouldn’t feed 100 hamburgers to your cat, you shouldn’t overload your anaerobic digester.

“Inline wastewater quality monitoring systems are available that allow users to identify high peak loads and buffer them from the system by gradually reintroducing them into the flow. By using this technology, you can identify high peaks and bypass them to a tank, drip feeding it back into the digester to avoid that high peak.

“By capturing valuable organics before they enter the anaerobic digester, a steady state condition of the digester can be maintained, which can increase gas generation.

“Installing a secondary anaerobic digestion (with a different type of methanogenic bug) downstream can improve biogas yield and wastewater treatment.”

Operating temperatures are also an important aspect to these systems. When it comes to controlling temperature, Australia has an advantage over Europe and the US. Ambient temperatures are warmer, so less energy is required to heat up wastewater streams and keep the bugs healthy and warm.

“But, if you accidentally dump hot water into the system, this could be damaging,” said Barker. “So managing your system with temperature control and redirecting anything that is potentially damaging is a good way to protect your anaerobic digester.”

AJ Bush

Future gazing

Although these systems are unlikely to provide enough power to make food processing sites self-sustaining, the energy the CAL system can produce is enormous. For example, one of Barker’s recent projects at a rendering plant is currently generating half a megawatt of power each day, which is all used back in the processing plant.

In the future, Barker said, this technology could be used for more factories located close to cities, such as breweries. “So, we need to fine-tune the systems to operate on a smaller footprint.”

Barker concluded by stating: “If there are organics in your wastewater, it is imperative that you do something with them.”

To discuss your Biogas and wastewater needs further, please contact Heath or Wiley.