Originally published in Australian Meat News, March 2016.

The meat industry is undergoing significant changes once more as consumer preferences, technology and regulation evolve. For abattoirs and processors to adapt needs new ways of thinking.

To meet those challenges, abattoirs, processors and supply chains must move forward – including upgrades to infrastructure and facilities.

Processing facilities eventually reach capacity and operate on outdated equipment making them unable to cope with expansion or changing market requirements. Planning and delivery of the facilities to meet future capacity and access local and international markets is a complex and risk laden business.

Australian Meat News will be exploring the processes involved in the delivery of projects and how new facilities and upgrades create value. Working with engineering-led design solutions company, Wiley, we will examine the upgrades underway at Northern Cooperative Meat Company (NCMC) in Casino, allowing us to see how a successful facility upgrade can be achieved.

For the past year, Wiley has been delivering significant works to NCMC’s brownfield site where four projects were identified. A new state-of-the-art cold chain management facility; design and construction of a beef knocking box and race system; design, supply and relocation of steam services and an upgrade to wastewater treatment at the tannery. These distinct deliverables aligned with NCMC’s vision for the site and each project had a business case to guarantee value was provided for years to come.

The Casino facility is approved for export to the USA, Japan, Korea and the EU and holds certification for organic and halal processing. The facility is capable of processing 12,500 cattle per week through slaughter, de-boning, processing, cold storage and packaging, rendering and tanning.

A traditional approach would follow a design, delivery and commissioning process. In the case of NCMC, Wiley used an alternative project management methodology, ‘design-build’ as a single contract. The ‘design-build’ approach takes the concept for the facility through all phases to final maintenance once completed.

In the initial phase Wiley and NCMC examined the NCMC business and its strategy, current challenges, objectives, how NCMC could execute their plans and how Wiley could assist. Detailed analysis was undertaken of the business inputs and consideration of how NCMC integrates with its key suppliers and delivery to their markets.

“To maximise the value of the project for NCMC and ensure every part of the opportunity was realised we followed a well-defined process,” said Wiley’s Senior Project Manager for the NCMC project, Barry Murphy.” We worked collaboratively with the client to understand the drivers in their business and examined each element. We looked at current processes, the existing facility and undertook physical review and analysis.”

“Determining NCMC’s project success criteria upfront was vital. Being responsible for a complex project in an actively operating facility presents challenges. Using our project management systems and the ‘design-build’ methodology to work with the client meant we could adjust as required and continue to plan and deliver. NCMC brought our team in early and we were able to work collaboratively to gain an understanding of the nature of their business challenges,” said Barry.

Barry Murphy is Wiley’s Senior Project Manager for the abattoir upgrade at Northern Cooperative Meat Company (NCMC)

Wiley’s project management approach on the NCMC project worked through a number of internally designed phases – discovery, concept, realise, define, deliver and maintain.

In order to remain globally competitive, the industry needs to be abreast of current technology and innovation for infrastructure and facilities. Wiley’s extensive experience and knowledge of current technology solutions has given the NCMC project significant advantages.

“We put significant effort into collaborating with technology providers during the discovery and concept phases to achieve a highly integrated solution for NCMC.”

“Our design and data teams analysed relevant portions of NCMC’s business, which highlighted that NCMC are a co-operative, meaning the number of key suppliers and diversity of product is larger than a corporate processing facility. This meant there were opportunities to dramatically improve efficiency around product packaging and handling,” said Barry.

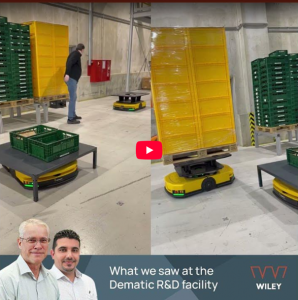

“As a result we were able to quantify a means of reducing product movement and associated multiple handling. This was achieved by implementing an ASRS (automated storage and retrieval system by Dematic). The NCMC carton shuttle system is the first in a frozen environment in Australia, and only the second in the world.” explained Barry.

The ASRS has storage capacity for 4,840 cartons and throughput of up to 14,000 cartons per day. This significantly reduced the handling of packaged product and will deliver large scale efficiency in processing and improved traceability.

The ‘design-build’ model used for collaboration between Wiley and NCMC is an unusual approach in the Australian industry. The model has maximised the efficiency of the project giving NCMC time and cost savings while still operating at full capacity as the project delivery moves forward.

The Knocking Box and Steam Services

The projects aside from the cold chain management facility include the design and construction of a beef knocking box and race system; design, supply and install of a steam repair and relocation and finally the tannery wastewater treatment plant upgrade.

NCMC Chief Executive Officer Simon Stahl said: “We have more than 100 operators who use our facilities in Casino to process their livestock. Our main focus is to provide them with efficient facilities using a highly trained workforce and specialised equipment to service our markets.

“We chose Wiley to undertake the design and construction of our latest projects because we are confident in their specialist knowledge of the demanding standards of food safety and hygiene, especially in meat and across the cold chain production line.

“The knocking box and race system are a pivotal part of our abattoir and will set the rhythm for the rest of the facility. Wiley have experience in designing to international standards of animal welfare and this design complied with design principles created by US animal welfare expert Dr Temple Grandin.”

The building for beef side of the knocking box project is now complete. The equipment was fitted offsite and commissioned early January this year. The first trial run of stock through the re-directed veal race was another successful milestone.

The steam services needed new gantry to ensure every aspect of the plant received steam, hot and cold water and compressed air

In January the steam system was commissioned to deliver steam, hot water and compressed air via the new services gantry to the new Knocking Box and other items of the plant. Previously, these services were delivered via the old gantry which was demolished as part of the overall upgrade.

“Although, this is the smallest of the four contracts we are currently delivering at NCMC, the delivery is integral to the success of other works being carried out and had more than its share of challenges,” said Barry.

“During the design process it was found that the existing structures at NCMC were incapable of supporting the loads identified during the steam design process which necessitated a substantial amount of creative design and provision of support structures within operating areas of the facility.”

“On-site access is limited due to working within an operating facility and an uninterrupted production output is a key deliverable of the project for the client. Therefore, our solution involved working to a schedule outside of the usual operating hours, sometimes through the night.”

The completion of the cold storage upgrade is due mid 2016 while the tannery is expected to be commissioned by June.