Shifting industry trends—Industry innovation and individualisation

Keeping our finger on the pulse, WILEY watch how packaging innovations and shifting consumer expectations are affecting the food industry.

Vodka giant Absolut has taken a leaf out of Coca-Cola’s book, dedicating themselves to a unique experiment in individualisation. Absolut have modified their production line to manufacture the ultimate in characteristically individual packaging; a processing line that has the potential to create 94 quintillion uniquely patterned bottles (that equates to more than 13 billion bottles per person in the world)!

ABSOLUT Unique: Behind The Scenes Video

Breaking away from the traditional bottle design involves a significant level of risk and has added complexity to the manufacturing process. Special algorithms were developed to create the unique patterns on each bottle. These algorithms were then used to print the bottles in custom designed printing machines using 35 colours and 51 patterns.

Naturally, this is a significant case of one-upmanship when compared with Coca-Cola’s ‘Share a Coke’ campaign late last year, in which the 150 most popular names in Australia were selected to be printed on personalised Coke bottles (Read the FoodMagazine article here).

On the back of that successful campaign, Coca-Cola will be looking to further enhance the Coke drinking experience by engaging consumers musically providing access to a predetermined playlist (Read the FoodMagazine article here). So, what do campaigns like this mean for manufacturing?

In the face of globalisation, multiculturalism, and mass production mentalities, many consumers feel that their identity is slowly being eroded away; but can they find the answer in a bottle? The more society commits to the notion of a global community the more urgent the need for individuality becomes. WILEY are watching this paradigm shift intensely.

The monopolies of retailing giants are standardising everyday consumer products and this is increasingly clashing with the growing consumer disillusionment with mass production techniques.

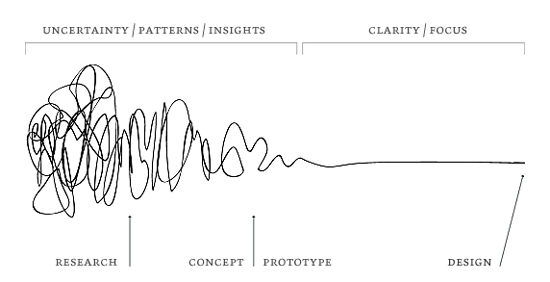

The evolution of mass production was predicated on increasing efficiency, decreasing labour costs, passing on savings, and streamlining processes. We’re now entering what economists are calling the Third Industrial Revolution where the means of production are becoming increasingly accessible to consumers demands. This accessibility to highly individualised products means that food producers and food processors need to start thinking about shifting their design thinking to align with consumer needs and expectations.

We are not witnessing the decline of mass production. Instead the food industry is seeing a shift in design thinking; the processing methodologies that focus solely on the finished product are fading fast. They are being replaced with philosophies that focus on consumer experience, satisfaction, and their need for a product that they can call their own.

WILEY provide adaptive and innovative strategies to assist our clients in assimilating to shifts like this within all areas of food processing.

About the author

Steve Christie is the Director of Process Engineering at WILEY and can be contacted on 1300 385 988 or email connect@wiley.com.au.